WhatsApp)

WhatsApp)

This section does not cite any sources. Please help improve this section by adding citations to reliable sources. Unsourced material may be challenged and removed.

Slag cement is a recovered byproduct of the iron manufacturing process and can be used to replace a portion of portland cement in concrete mix design.

TECHNOLOGICAL UPGRADATION OF CHUNAR CEMENT GRINDING UNIT,, CHUNAR CEMENT FACTORY (A Unit of Jaiprakash Associates Ltd. India)

Cementitious Materials Introduction Cement is the adhesive or glue, which when set binds particles of fine aggregate together to produce mortar. When mixed with water ...

Hannibal Plant Process Engineer Job Description. POSITION TITLE: Hannibal Plant Process Engineer REPORTS TO: Production Manager LOCATION: Hannibal Cement .

Cement mill. Cemax full range of cement grinding aids and performance enhancer, formulated to increase cement mill throughput, reduce cement production cost and ...

Dry, semidry, semiwet and wet processes are the four main process routes that are used for the production of cement. Dry processes are considerably more energy ...

Almost everyone interested in cement is also concerned to at least some degree with concrete strength. This ebook describes ten cementrelated characteristics of ...

Wet and semiwet process cement kilns ... It is this thin layer of water that allows the slurry to flow. As the separation of particles increases with increasing ...

Reducing greenhouse gasses emissions by fostering the deployment of alternative raw materials and energy sources in the cleaner cement manufacturing process

Grinding Leveling Grinding concrete eliminates raised trip hazards in sidewalks and other walkways. If you have a business, the Canadians with Disabilities Act ...

industrial case study: the cement industry calmac study id: final report prepared for pacific gas and electric company san francisco, california

FL wins cement grinding plant contract in Nepal FL has signed a contract with Nepal Shalimar Private Limited for engineering, procurement and supply of ...

Dental veneers can improve the appearance of your teeth. Find out the pros and cons of veneers from the experts at WebMD.

In the cement pyroprocessing process it is important to keep in mind that waste materials combust and burn at different temperatures under different conditions.

1 2 3 4 5 6 7 8 9 10 F Production and facilities information COMPOSITION AND PRODUCTION OF CEMENT Cement is made by crushing and grinding calcium carbonate (limestone ...

CEMENT where quality and sustainability are everyday priorities LAFARGE LICHTENBURG CEMENT WORKS Lichtenburg Works is our flagship cement production

Hi Liz, Firstly, thank you for your tips and advice! You are a really awesome teacher! I have a question for a description of a process. One website (endorsed by IDP ...

Chemical Considerations. The raw material preparation stage of cement manufacture results in the production of a rawmix that is in a suitable state for feeding to the ...

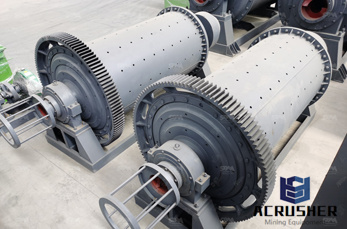

Cement grinding Vertical roller mills versus ball mills Soeren Worre Joergensen MSc, General Manager, Engineering, Grinding Technology

Specialized foundry of premium wear parts for aggregate, recycling, mining and cement plants. Blowbars, cones, jaws, liners, kiln inlet, cooler grates, ceramic insert ...

Web portal for buildingrelated information with a "whole building" focus provided by the National Institute of Building Sciences. Areas include Design Guidance ...

GRINDING MEDIA FOR THE VARIATIONS IN CEMENT MANUFACTURING. Changing impact conditions can cause conventional grinding media to either work harden or cause .

2 entrained mortar materials may increase initial bond strength, but may also reduce workability and resistance to freezethaw deterioration. Specifiers should ...

WhatsApp)

WhatsApp)