WhatsApp)

WhatsApp)

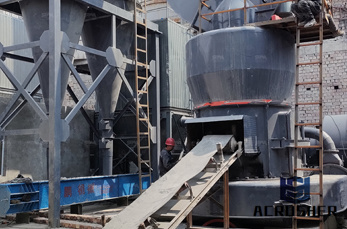

efficiency of cement ballmi CGM mining application. Sell highly efficient rod mill/grinder from professioal manufacturer Sell high efficiency cement mill for For more ...

Energy Efficiency and CO 2 Reduction in the Cement Industry SETIS In brief The most important use of cement is in the production of concrete. It acts as the binder

Cement Plants Scribd. HANDBOOK FOR DESIGNING CEMENT PLANTS "This page is ... grit separators, mechanical air separators; High efficiency ...

ii Energy Efficiency Improvement and Cost Saving Opportunities for Cement Making An ENERGY STAR® Guide for Energy and Plant Managers Ernst Worrell, University of .

THE GNCS FACTSHEETS Mitigating Emissions from Cement ... Cement consumption is growing at % annually,7 and at current technological levels and efficiency rates, CO 2

Crusher Pemasok Di Sa . efficiency of cement ballmi. Crusher; Mill; Mineral; About Us; Contact Us; Crushers, Screen, washing, Feeder, conveyor for efficiency of ...

1 LBNL44182 Energy Efficiency and Carbon Dioxide Emissions Reduction Opportunities in the Cement Industry Nathan Martin, Ernst Worrell, and Lynn Price

AVAILABLE AND EMERGING TECHNOLOGIES FOR ... Emerging Technologies for Reducing Greenhouse Gas ... greater fuel efficiency compared to other types of cement

Energy Efficiency and CoBenefits Assessment of Large Industrial Sources Cement Sector Public Report California Air Resources Board Stationary Source Division

The potential opportunities for improving energy efficiency and lower CO 2 emissions in raw material generation and production of concrete are smaller than in cement ...

In, the Cement Sustainability Initiative (CSI), operating under the ... Electric energy efficiency MWh/tonne cement 111 % . 5/43

Use of Fly Ash in Concrete: Efficiency Factors of the Supplementary Cementing Material Michele Valente 1, Michele Vigneri, Marco Bressan1, Alessandro Pasqualini,

energy efficiency in the cement industry j sirchis serpolhyr de efficiency of cement ballmi processing machinery for the cement energy efficiency vertical

Alternative Energy Sources in Cement Manufacturing 3 Dear Reader, I am pleased to share the Network for Business Sustainability‟s report on the use of

Energy Efficiency Improvement Opportunities for the Cement Industry Ernst Worrell, Christina Galitsky and Lynn Price Environmental Energy Technologies Division

· I have to audit thermal efficiency of cement kiln system. I''ve made mass and heat balance for that system. Heat inputs consist of raw mix heat, air heat,...

Energy optimization in cement manufacturing Reprint from ABB Review 2/2007 Cement producers are large consumers of thermal and electrical energy, which on a global ...

Industrial Decarbonisation Energy Efficiency Roadmaps to 2050 MARCH 2015 ... INDUSTRIAL DECARBONISATION AND ENERGY EFFICIENCY ROADMAPS TO 2050 – CEMENT

Feed Back. Analysis of material flow and consumption in . Abstract. Cement production, which is highly dependent on the availability of natural resources, will face ...

Climate Technology Development: Energy efficiency and GHG reduction in the cement industry Case study of SubSaran Africa Raluca Ionita (ECN)

MEASURING IMPROVEMENT IN THE ENERGY PERFORMANCE OF ... MEASURING IMPROVEMENT IN THE ENERGY PERFORMANCE ... the ENERGY STAR Focus on Energy Efficiency in Cement

CEMENT AND LIME MANUFACTURING APRIL 30, 2007 1 WORLD BANK GROUP Environmental, Health, and Safety Guidelines for ... efficiency (dry/ preheater / calciner);

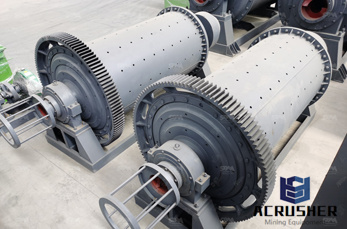

Cement grinding Vertical roller mills versus ball ... cement industry the ball mill was really an epochmaking ... The grinding efficiency of the vertical roller ...

Processing Equipment For Kaolin,Industrial Minerals Grinding ... ... Ball mills for sale prices,cement ball mill ... The Cement Ball Mill is a high ...

WhatsApp)

WhatsApp)