WhatsApp)

WhatsApp)

The basic parameters used in ball mill design (power calculations), rod mill or any tumbling mill sizing are; material to be ground, characteristics, Bond Work Index ...

ball mill operation New questions Operation Of Ball Mill In Pdf 37 Views. The is the professional mining equipmentsmanufacturer in the world,Operation ...

Cement manufacturing brief description of a cement mill. Cement clinker is usually ground using a ball mill. This is essentially a large rotating drum containing ...

What Is Ball Mill And Its Working Principle? The usage of ball mill and its technical data Ball mill is widely used for grinding ores and rocks in metal and nonmetal ...

Ball mill operation and maintenance. To make the ball mill operate good, we must strictly abide by the operation and maintenance procedures. Before starting the ball ...

China Ball Mill manufacturers Select 2017 high quality Ball Mill products in best price from certified Chinese Milling manufacturers, Plastic Machinery factory ...

ball mill operation process crusher in India In Namibia. In Namibia Grinding Mill. Grinding is the required powdering or pulverizing process when final size of below ...

Synthesis of Nanomaterials by High Energy Ball ... It is a ball milling process where a powder mixture placed in the ball mill is subjected to highenergy collision ...

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is ...

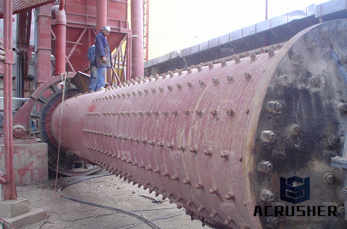

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering.

Ball mill grinding operation is to continue the process of crushing the ore, is the preparation work of sorting an important part of the ore in the last before the ...

ball mill operation process. Process shift supervisor profiles LinkedIn Professionals with the job title Process shift supervisor are on LinkedIn. ...

When the ball mill works, motor and speed reducer transmit torque force to big and small gears of ball mill, so the barrel the barrel rotates, Steel ...

1. Introduction. Ball mill grinding is a fundamental operation process, and in many respects the most important unit operation in a mineral processing plant.

Ball Mill Processball mill process Ball Mill Introduction: The ball mill is the key equipment for the material to be broken, and then crushed. The ball mill is widely ...

Optimization of Cement Grinding Operation in Ball Mills. Contact Us » Several energy efficient options for cement grinding are available today such as vertical ...

ball mill process – Coal processing system Machine for sale. Find the Right and the Top ball mill process for your coal handling plant! , a mining machines ...

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

· Overflow Discharge Ball Mill in Operation in a RockPhosphate Processing Plant. For more videos related to Mineral Processing visit my YouTube channel :

ball mill process of operation . Ball mill Wikipedia, the free encyclopedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral ...

Ball Milling An efficient and ... What is ball milling? A ball mill is a type of grinder used to grind materials into extremely fine powder. 7 . ... process Tip of

ball mill operation and maintenance. OrientalBall Mill,Ball Mill For Sales,Price List,Manufacturer. ... Ball Mill Drives Process Advantages Mining Congress.

KURIMOTO, LTD. Product Information, Horizontal Grinding Mill Overflow Type, Gratedischarge Type, and Compartment Type Ball Mill

Ball Mill and Grinding Circuit Preparation for StartUP The following items must be checked before the equipment in the Grinding Circuit is started.

WhatsApp)

WhatsApp)