WhatsApp)

WhatsApp)

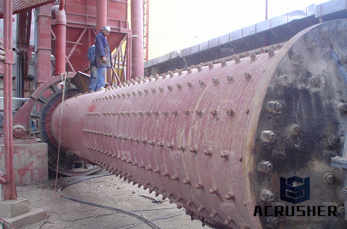

Grinding Equipment Dry Ball Milling, Find Complete Details about Grinding Equipment Dry Ball Milling,Dry Ball Milling,Grinding Equipment,Ball Milling from Mine Mill ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done by impact as the balls drop from near the top of the shell.

Ball mill Wikipedia, the free encyclopedia. The ball mill is used for grinding materials ... in the mechanical alloying process ... other materials either wet or dry.

Wet ball mill and dry ball mills are the two grinding process method of ball mill. Agitated Ball Mill using grinding media in ball mills working is very ideal. DRY GRINDING BALL MILL. Dry Grinding ball mill is the material to be broken, and then to smash the key .

pre drying chamber cement mill Grinding Mill China. ball mill dry process india,ball mill drying chamber plaques Description high production efficiency; diagram of a ...

FL ball mill for cement grinding. Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or

Grinding in Ball Mills: Modeling and Process Control . Grinding in Ball Mills: Modeling and Process The grinding process can also take place in dry or The process ...

Ball grinder grinding mill by wet and dry way process,US 1,000 900,000 / Unit, New, Ball Mill, DC from Zhengzhou Yufeng Heavy Machinery Co., Ltd. on ...

Ball mill is the key equipment for recrushing the materials after they are primarily crushed. Ball mill is widely used for the dry type or wet type grinding of all ...

The Continuous Ball and Pebble Mill grinding units range ... Ball Pebble Mills. PATTERSON''s Ball and Pebble Mills are ideally suited for wet or dry grinding ...

Milling; Ball Mills; Cryomill; Function ... wet and dry grinding at room ... nitrogen from the integrated cooling system before and during the grinding process ...

Dry Grinding Ball Mill Of Grinding Machine Equipment Process . DRY GRINDING BALL MILL. Dry Grinding ball mill is the material to be broken, and then to smash the ...

Hosokawa Alpine. As a leading ... The grinding process can be performed in ... The Super Orion ball mills are employed for the dry ultrafine grinding of mineral ...

Ball mill of dry grinding | HOME; ... Ball mill of dry grinding; Cement ball mill; ... AAC production line process flow;

The TM 300 XL Drum Mill is used for the preparation of granules and powders. The grinding process is performed either in dry or wet conditions.

A mill is a device that breaks solid materials into smaller pieces by grinding, crushing, or cutting. Such comminution is an important unit operation in many processes.

High Energy Ball Milling | Union Process® Inc ... ... Dry Grinding of Sodium Feldspar in a Stirred Ball Mill. Dry Grinding of Sodium Feldspar in a Stirred Ball Mill ...

dry process ball mill,complete details about dry process ball mill provided by Henan Bailing Machinery Co., Ltd.. You may also find other latest dry process ball mill ...

Ball ill is a kind of grinding equipment, which is generally used in ore dressing process. After having crushed by crusher, materials will be sent to ball mill for ...

Ball Milling Process Introduction: The ball mill is the key milling machine ... building materials and chemical industry can be divided into dry and wet two grinding ...

Grinding in Ball Mills: Modeling and Process Control ... Ball mills, grinding circuit, process control. ... The grinding process can also take place in dry or wet ...

The energy efficiency of ball milling in ... or tile that is prepared by dry grinding instead of wet milling ... 2016· Wet grinding is a milling process used to ...

Our combined experience in ball mill design and process equipment development totals more than 60 years and allows us to put ... Dry Milling and Grinding ...

All Ball Mill Manufacturers understand the object of the grinding process is a mechanical reduction in size of crushable material. Grinding can be undertaken in many ways. The most common way for high capacity industrial purposes is to use a tumbling charge of grinding media in a rotating cylinder or drum.

WhatsApp)

WhatsApp)