WhatsApp)

WhatsApp)

J o u r n a l P a p e r Introduction The performance of tumbling mills is sensitive to the volumetric mill filling which influences grinding media wear rates, throughput, power draw, and product grind size from the circuit. Each of these ...

IV. BALL MILLS Ball mills are one of the more common mills and use a closed cylindrical container that is rotated horizontally on its axis so that the media cascades. A typical ball mill has an L/D ratio of :1. Ball mills are filled ...

Versatile system based on standard modules 2 The FL ball mill is designed for grinding of clinker, gypsum and dry or moist additives to any type of cement. The mill may operate in either open or closed circuit and with or ...

Ball mill A typical type of fine grinder is the ball mill. A slightly inclined or horizontal rotating cylinder is partially filled with balls, usually stone or metal, which grind material to the necessary fineness by friction and impact with the ...

Grinding Media is used to finely grind ore material to a size which allows recovery of the desired contained material. ... Many choices for grinding media. Photo shows (clockwise from top right) ceramic, plastic, steel and glass media.

2010/09/08· Documents Similar To Ball Mill Grinding Media Skip carousel Ball Mill Grinding Media Max Ball Size Calculation Grinding Media Composition and Quality Cement Mill Control DB MS OK Mill Symposuim Indonesia2 Raw Material ...

Grinding Media, Glass Beads, Zirconium Silicate, . Guide to Selecting Mill Media. Particle Size Conversion Chart. YTZ ® Grinding Media The highest density, highest quality grinding media available! » Learn More ball mill steel ball ...

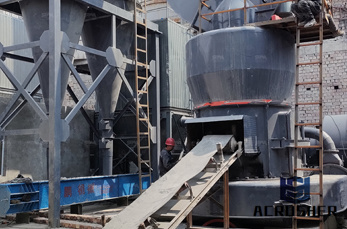

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement. Most cement is currently ground in ball mills and also vertical ...

The ball mill crushes materials through the impact and grinding effect of the grinding media. In this process, the steel ball is used a medium of energy to transform the outside energy to the crushing forces, thus completing the ...

A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing processes, paints, pyrotechnics, ceramics and selective laser sintering. It works on the principle of impact and attrition: size reduction is done ...

EFFECTS OF GRINDING MEDIA SHAPES ON BALL MILL PERFORMANCE Niyoshaka Nistlaba Stanley Lameck A dissertation submitted to the Faculty of Engineering and The Built Environment, University of the Witwatersrand ...

1. Introduction The ball size is one of the critical factors for determining the mill performance of ball mills. It is well known that larger balls are needed for the effective breakage of largesize particles, whereas smaller balls are more ...

III. HIGH CIRCULATION MILLS (ATTRITOR AND NEW, SMALL MEDIA QCMILL) CIRCULATION ATTRITORS – Q MACHINES In recent years, many paint and mill manufacturers have focused much of their attention towards a "new" ...

savings are far greater than 50% of ball mill energy in finegrinds. Media Savings Media consumption is directly related with energy efficiency. At a concentrator in Mexico, they experienced reduced media consumption from a previous ...

FOX Chrome Steel Balls will transform your ball mill operation into a lean, mean, grinding machine. Find out why you should use FOX Chrome Steel Grinding Balls. FOX Industries Industrial media to keep you up and running. ...

Planetary Ball Mill PM 200 RETSCH short grinding The Planetary Ball Mill PM 200 is an excellent choice when a high degree of fineness is required. Grinding down to the nano range. Read more. >> Get Price Ceramic Lined Ball ...

In Grinding, selecting (calculate) the correct or optimum ball size that allows for the best and optimum/ideal or target grind size to be achieved by your ball mill is an important thing for a Mineral Processing Engineer AKA Metallurgist ...

As a prerequisite to producing superclean coal with any physical coalcleaning process, such as microbubble flotation, the feed coal must be micronized to liberate finely disseminated mineral matter. The stirred ball mill is regarded ...

Ball mills media Reset Filters Shop by Price Availability In Stock Out of Stock Ball mills media Product Compare (0) Show: Sort By: 100 watt converter plug adapters Plug Adapters Will Fit Our 100 Watt Power Converter Sold ...

This formula calculates the critical speed of any ball mill. Most ball mills operate most efficiently between 65% and 75% of their critical speed. Photo of a 10 Ft diameter by 32 Ft long ball mill in a Cement Plant.

An online calculator lets you calculate Top Ball Size of Grinding Media for your mill. Use this Equation Method to properly grind your ore. An online calculator lets you calculate Top Ball Size of Grinding Media for your mill. Use ...

Ball Mill Loading Dry Milling Ball Mill Loading (dry milling) When charging a ball mill, ceramic lined mill, pebble mill, jar mill or laboratory jar use on a jar rolling mill it is important to have the correct amount of media and correct ...

Effect of the size of media on grinding performance in This work investigated the effect of grinding medium size on the wet milling performance in stirred mills using

The optimal ball diameter in a mill 333 The grinding efficiency of the narrow particle size fractions with ball charge of various diameters has been observed through the constant of milling rate k in the

WhatsApp)

WhatsApp)