WhatsApp)

WhatsApp)

Process for Making Concrete. Concrete is comprised of different sizes of aggregate, sand, admixtures, water, and Portland cement. These raw materials are stored in ...

improve of cement making process, From large primary jaws and gyratories to cones and VSIs for tertiary and quaternary finishing, ... typical cement making process ...

Keywords: Cement industry, computer control, adaptive control, stochastic control, process identification Contents 1. Introduction 2. ... Typical cement grinding mill

sand making. sand washer; ... Typical Cement Production Plant Layout,Shanghai XSM is a professional ore crusher equipment,Typical Cement ... Cement Production Process.

Within this process lies the key to a remarkable trait of concrete: ... The watercement ratio is the weight of the mixing water divided by the weight of the cement.

Cement kiln | Dry and Wet Processes. Over a billion tonnes of cement are made per annum, and the cement kiln is the heart of this [..], Cement typical process ...

Nov 15, 2007· Cement making process. I don''t owe any copyrights for this video. I just uploaded it because there was no good video about cement making process .

The chemical process for hydraulic cement found by ancient Romans used volcanic ash ... which described the various methods of making cement and concrete, ...

Chapter 1 Introduction to Cement Production. Burning the blended materials is the key in the process of making cement. one being adopted for virtually all new ...

This is a complex process that is best understood by first understanding the chemical composition of cement. ... The cement clinker formed has the following typical ...

Optimization of the clinker making process is usually ... of process control and optimization systems make use advancements in ... for Cement Making, ...

Designing Concrete Mixtures ... Process of measuring the slump of fresh concrete ACI Mix Design Process of measuring the slump of fresh concrete ACI Mix Design

CEMENT INDUSTRY Output of a Seminar ... process of cementmaking and effective use of industrial ... A typical example of the wet process is a straight cylindrical ...

Portland Cement Manufacturing; Basic Information; ... Portland cement manufacturing is an energyintensive process that grinds and heats a mixture of raw materials ...

How To Making Fiber Cement on Hatschek Machine and ... process diagram of a typical coal mine plant; gypsum powder process; cement manufacturing process in .

typical cement plant layout ... Sand making machine is the most widely used equipment in artificial sand making ... Cement . EDEC offers Process, Electrical, ...

A typical limestone/cement rock quarrying process for producing crushed and broken ... The burning of limestone in the cementmaking process liberates carbon ...

Cement manufacturing is not as complex as it seems to be. To make cement, industrial plants follow step by step systematic process. Here is a brief guide on how to ...

Cement production process route ... Many of the aspects of the cement making process are potentially ... Flow Diagram for Portland Cement ...

Wet process kilns. The original rotary cement kilns were called ''wet process'' kilns. In their basic form they were relatively simple compared with modern developments.

A typical process of manufacture consists of ... in a cement kiln; grinding the resulting clinker ... kilns as large as x 225 m in size were making 3000 tonnes ...

Cement, or Portland cement, ... fly ash, bauxite, alumina process waste, and granite. Some typical materials used for silica in cement manufacturing are sand, ...

IXMaterialsBCement1 THE MANUFACTURE OF PORTLAND CEMENT ... making a network in which the ... The cement manufacturing process involves four ...

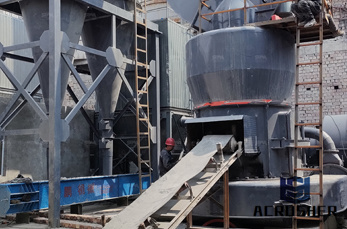

Typical sampling points in a cement plant . for quality and compliance, as well as for making process adjustments, include: • Raw meal prior to storage

WhatsApp)

WhatsApp)